Status

Description

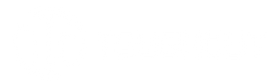

The Toughcut Cobalt 25 edge bander is an entry-level machine designed for small cabinet shops whilst having many of the features of its bigger brother Nickel 35. This machine is designed to have a small footprint whilst giving a quality finish to the product. The Cobalt series offers a feed speed of 7m/min. with double-end, saws along with flush trimming, glue scraping, and buffing this machine has all the right features. The Cobalt edge bander range offers consistent performance and superior reliability with easy-to-use and uncomplicated adjustments. It is the ideal starter for your new, boutique, start-up business.

Features

- TOUCH SCREEN CONTROL – User-friendly touch screen control and interface ensures quick and easy execution of customized working programs

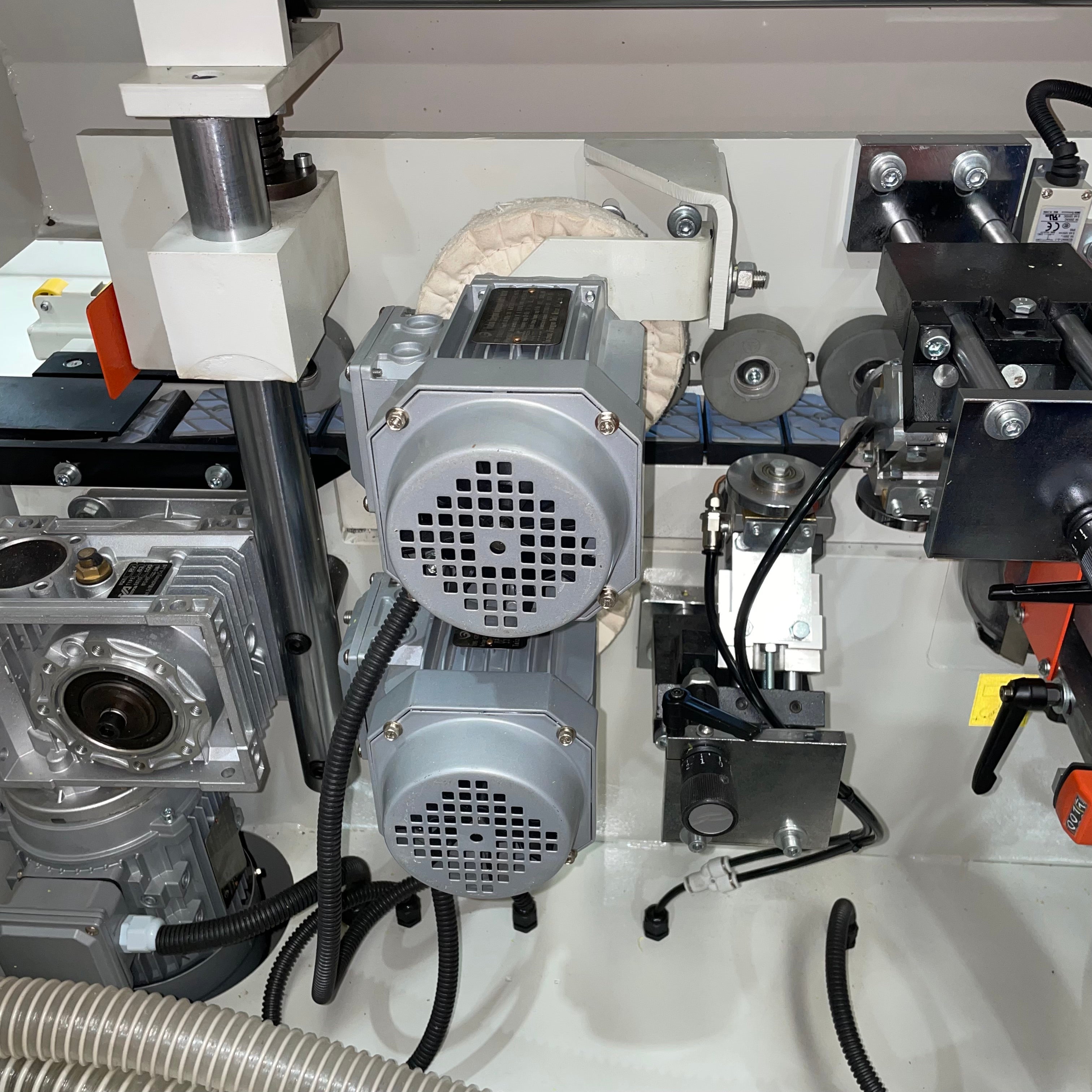

- END CUTTING UNIT – With two independent high-frequency motors to cut the front and rear edge. Each operating motor is equipped with a copying device for accurate positioning of blades in relation to the cutting point.

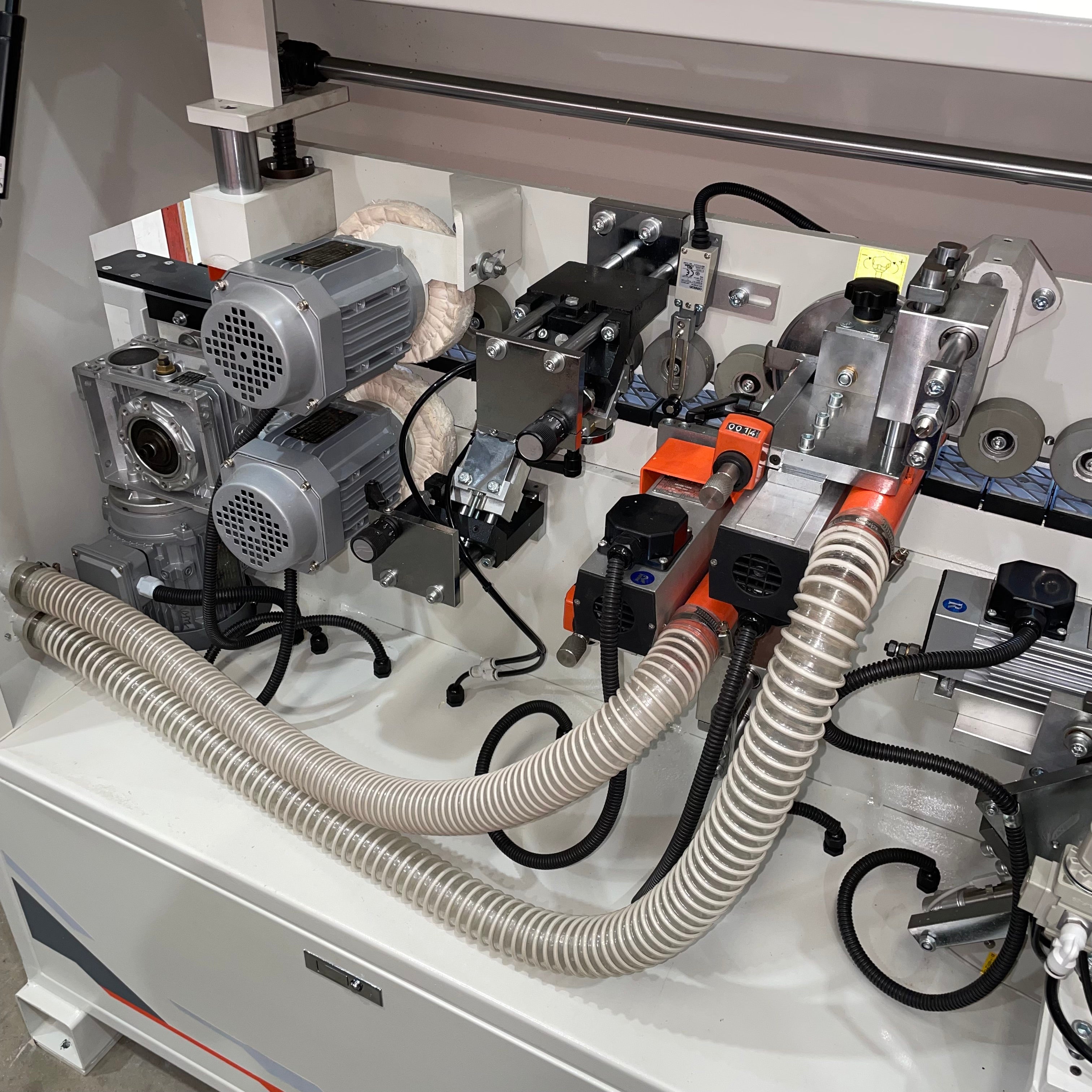

- FLUSH TRIMMING UNIT – Equipped with two independent high-frequency motors mounted on support firmly fixed to the frame to carry out the trimming of the bottom/top exceeding edge. Each motor is equipped with vertical rotation copying devices and a front copying pad, easy-to-read digital adjustment, and accurate positioning of tools with reference to the trimming.

- RADIUS GLUE SCRAPER – Manually adjustable scraper knives ensure a perfect finish on the panel surface

BUFFING UNIT – With Two independent motors for the buffing/polishing of the edge

- GLUE APPLICATION UNIT – The quick detachable glue pot provides easy cleaning of glue residue, reducing the downtime in cleaning and maintenance. Automated glue control prevents glue from burning when the machine is on standby, thus preventing glue carbonization and ensuring energy efficiency.

Youtube video of the Edgebander can be viewed below:

1. Toughcut Cobalt 25 Semi Automatic Hot Melt Edge Bander Commissioning here